Gain Precise Control when Coating on a Converting Line

The Epic Precision Liquid Applicator (PLA) is a contact roll moisturizing system that uses hydrophilic chrome roll technology for moisture addition, moisture profiling and curl control at high production speeds for paper making and converting applications.

The PLA also provides reliable and cost-efficient accuracy in the application of aqueous, solvent based, catalytic, electron beam, UV or carbonless coatings. It is designed to be used in a wide range of coating functions, including single or simultaneous double-sided coating.

PLA

- Hydrophilic chrome roll technology for contact moisturizing

- Designed for moisture addition, moisture profiling, curl control, surface coating, controlled penetration coating for paper manufacturing and converting

- Maintains a constant and accurate lay down at roll speeds of 5000 fpm

- Safe and simple to operate

- Fast and easy single operator control

- Roll-to-roll pressures and skewing measured by dial indicator and adjusted via hand-wheels with internal scales

- Requires no viscosity adjustment for speed changes

- Reduces production waste

- Less coating needed to deliver pin hole and pattern free coating

- Cost effective

- Precise

- No slinging or spattering

- Single or simultaneous double sided application

- Delivers a constant film thickness at any web speed

- Supports wide range of coatings including: aqueous,

solvent based, catalytic, electron beam, UV or carbonless - Transfers liquid films from 3 to 15 microns thick

3 Mode Functions

- Ideally suited for controlling web curl under demanding paper and broad processing conditions

- Decurls the web through the controlled penetration of water into the sheet

- Close tolerance addition of moisture relaxes the sheet, eliminating curl

- Creates a consistently flat surface

- Drives moisture into the sheet fibers producing virtually no surface moisture

- Accurately and reliably applies moisture to virtually

any paper or board, at full production speeds

- Provides accurate and dependable single sided coating

- Allows close regulation of material application, with constant coat weight regardless of speed

- Able to run varying web widths without edge buildup

- Designed for web following and automatic startup and shutdown

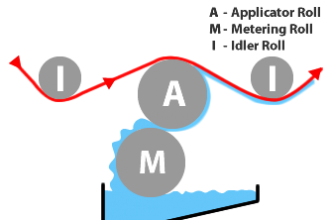

- Supports both forward and reverse roll coatings

- Installed with a horizontal web path arrangement

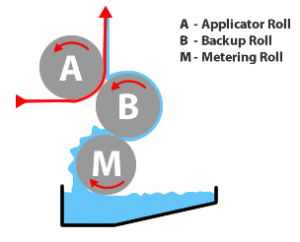

- Simultaneously applies the same or different coatings

to both sides of the web - Costs less and takes up less space than installing two

separate coaters

- Installed with a horizontal web path arrangement

- Simultaneously applies the same or different coatings to both sides of the web

- Costs less and takes up less space than installing two separate coaters