Upgrade a Metal Decorating Press with Epic Delta Dampening

With the high cost of tin plate and the demand for flawless print, metal decorators strive to control waste and quality. By retrofitting a metal press with Epic’s Delta Dampening System, virtually defect-free printing can be achieved – minimizing waste, reducing press down time and saving hours of product inspection.

With the high cost of tin plate and the demand for flawless print, metal decorators strive to control waste and quality. By retrofitting a metal press with Epic’s Delta Dampening System, virtually defect-free printing can be achieved – minimizing waste, reducing press down time and saving hours of product inspection.

How much can Epic Delta Dampening System save you?

The improved print quality, combined with the efficiencies gained in productivity, result in a rapid return-on-investment.

- Hickey-free printing – guaranteed

- Faster make readies, 30% fewer sheets

- Reduce waste – virtually no press stops to remove hickeys

- Gain precise control over ink/water balance

- Smoother, denser solids

- Reduced ghosting and streaking

- Sharper half-tones with less dot gain

- Print sharper images and cleaner reverses

- Tighter screens without plugging

- Excellent color control and consistency

- Dampening form roller is separate from the inking system, allowing for the retention of all ink form rollers

- Crabtree Marquess

- HOE

- KBA Metalstar

- Primex

- Mailander

- MAN

- Toyo Seikan

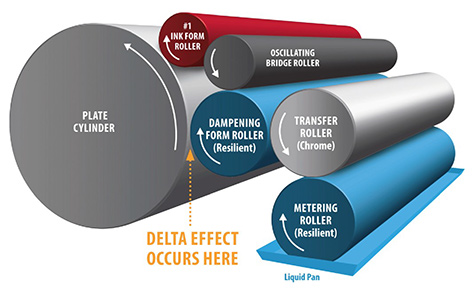

How it Works

The unique Delta design utilizes helical gears and positive roller settings to drive the dampening form roller at a slower surface speed than the plate cylinder. The differential motion, called the “Delta Effect” wipes away the foreign particles that cause hickeys, while continuously allowing a fresh charge of ink to the plate.