Add Precision Coating to an Existing Press Epic’s CoatTech™ Anilox Coating System

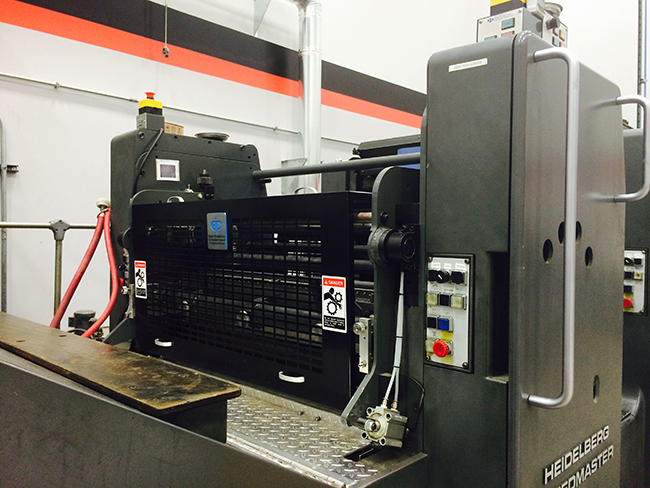

No need to buy a new press – add an additional anilox unit to a press or upgrade your tower coater to anilox.

One pass productivity is necessary in today’s market. The Epic CoatTech offers precision and versatility to your offset press. CoatTech applies a consistent coating thickness and supports a broad range of substrates and finishes. By installing Epic’s CoatTech system, users will experience superior performance, improved efficiencies and ultimately significant cost savings.

Three ways to add a CoatTech Anilox Coating System to an Existing Press

- Permanently convert an existing print station to a CoatTech coating station (Stationary Blanket Coater/SBC)

- Convert a 2-color press into an off-line coater unit

- Install a retractable CoatTech system (Retractable Blanket Coater/RBC)

- Custom engineered to fit most presses

- Uniform coating thickness and precise edges

- Supports UV, aqueous, metallics, specialty coatings, primers, tints, blister seal, gloss, dull, satin and more

- Precise spot coating

- Eliminates orange peel, ribbing and streaking

- Chamber-in-chamber system prevents coating from leaking into press

- Fast and efficient clean up

- Reduces operating costs – less waste, ease-of-use, lower coating usage and requires fewer anilox rollers

- Enclosed fountain with doctor blades – quick release system for fast clean-up and easy change out

- Anilox roller removes easily to accommodate coating changes

- Either vertical or horizontal retraction mechanism, position for printing or coating mode

- Laser engraved, lightweight carbon fiber anilox roller provided as applicator to blanket – cell size to customer’s specifications

- Operator’s control station with necessary selector switches and controls

- Manual mode – operator controls anilox roller to blanket cylinder

- Automatic mode – anilox roller will activate when the printing unit goes on pressure

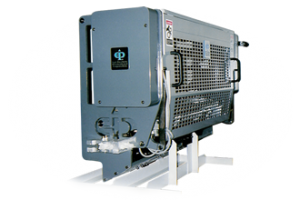

- Integrated coating pump console – all pump and wash up functions located in a single freestanding enclosure – suitable for UV or aqueous

- All necessary brackets, side frames, etc. to geometrically locate and hold the coater in place on the press

- Custom painted to match press

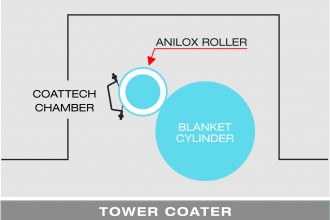

Tower Coater Conversion from Roller to Anilox Metering

- Uniform coating thickness and precise edges

- Supports UV, aqueous, metallics, specialty coatings, primers, tints, blister seal, gloss, dull, satin and more

- Precise spot coating

- Eliminates orange peel, ribbing and streaking

- Fast and efficient clean up

- Reduces operating costs by an average of 25% – less waste, ease-of-use, lower coating usage and requires fewer anilox rollers

- Enclosed fountain with doctor blades – quick release system for fast clean-up and easy change out

- Anilox roller removes easily to accommodate coating changes

- Laser Engraved, lightweight carbon fiber anilox roller provided as applicator to blanket – cell size to customer’s specifications

- Operator’s control station with necessary selector switches and controls

- Manual mode – operator controls anilox roller to blanket cylinder

- Automatic mode – anilox roller will activate when the printing unit goes on pressure

- Integrated coating pump console – all pump and wash up functions located in a single freestanding enclosure – suitable for UV or aqueous

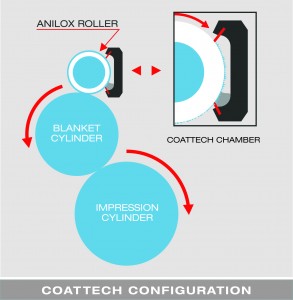

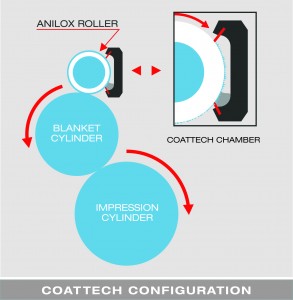

- Coating flows into the chamber from the CoatTech Circulator

- Coating is metered to the anilox roller from the chamber

- Coating precisely metered from anilox roll to the blanket

- The servo drive powers the anilox roller and is speed tracked to the press via an encoder and PLC control system

- The anilox roller can be reduced in speed in relation to the blanket cylinder

Ancillary Items

- All pump and wash-up functions in a single freestanding enclosure for ease of operation

- Double diaphragm pumps for positive pressure and suction. Suitable for UV or aqueous coatings

- Inlet for water or UV wash-up solution allows fast clean-up or coating changes

- Two air knife assemblies for installation, stainless steel, adjustable for angle of air impingement

- One – 3 H.P., high-pressure, high volume blower

- All necessary brackets, duct and electrical controls required for operation

- Air temperature adjustable by solid state SCR control